Surface Integrity: The Importance of Inspection

Surface integrity is a critical aspect of material quality, especially in industries where the slightest imperfection can lead to catastrophic failures. This includes sectors like aerospace, automotive, and biomedical devices, where the reliability and safety of components are paramount.

Modern inspection techniques play a vital role in ensuring that surface conditions meet stringent standards, helping to prevent failures and extend the lifespan of materials. In this article, we will delve into some of the latest methods used to inspect and maintain surface integrity.

Non-Destructive Evaluation (NDE): A Closer Look at Surfaces

Non-destructive evaluation (NDE) techniques allow inspectors to assess the condition of a component without causing damage. Among these techniques, dye penetrant testing stands out for its simplicity and effectiveness in detecting surface-breaking defects in non-porous materials. This method involves applying a visible or fluorescent dye to the clean surface of a component, where it seeps into any cracks or defects. After a period, the excess dye is removed, and a developer is applied, drawing the dye out of the defects to reveal their presence visually.

Visual Inspection: The First Line of Defense

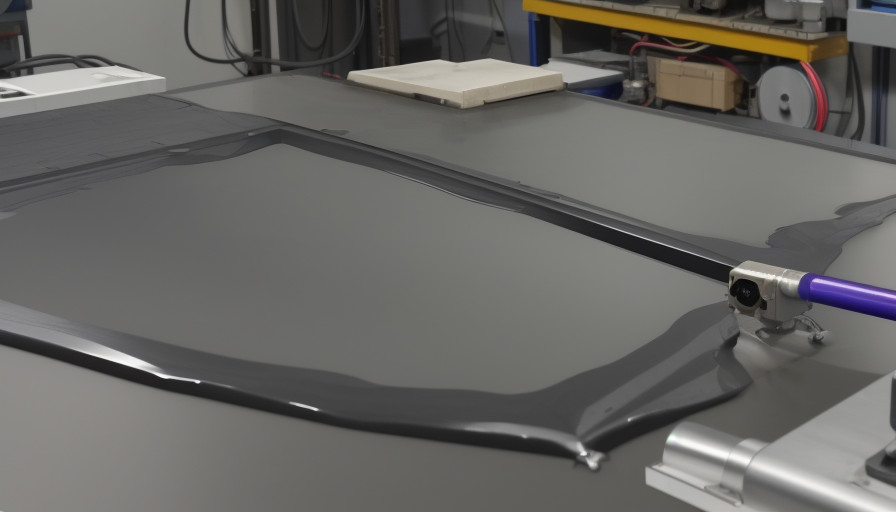

Visual inspection, though one of the oldest methods, remains a fundamental first step in surface integrity assessment. With advancements in technology, this technique now often incorporates various tools such as high-definition cameras, magnification devices, and specialized lighting systems to enhance the detection of surface flaws that are invisible to the naked eye.

Eddy Current Testing: Harnessing Electromagnetic Fields

Eddy current testing is another effective technique for examining surface and sub-surface defects. This method uses electromagnetic coils to induce eddy currents in conductive materials. Flaws in the material alter the flow of these currents, which can be detected using sophisticated sensors. The data collected provides detailed information about the presence and characteristics of surface defects.

Advanced Techniques for Enhanced Accuracy

As technology evolves, so do the techniques we use to inspect surface integrity. These advanced methods offer greater accuracy and deeper insights into material conditions.

Laser Scanning: Precision and Speed

Laser scanning technology provides a fast and highly precise way to inspect surfaces. It works by projecting a laser beam onto a surface and measuring the time it takes for the light to bounce back to a sensor. This data is then used to create detailed 3D models of the surface, highlighting imperfections such as scratches, pits, and other irregularities.

Thermography: Seeing Beyond the Visible

Infrared thermography is a technique that detects infrared energy emitted from an object and converts it into temperature data to create thermal images. This method is particularly useful for identifying changes in materials that affect their thermal conductivity. Defects such as delaminations, cracks, and other discontinuities can be detected by observing variations in thermal conductivity across a component’s surface.

Integrating Technology: The Role of Digital Tools

The integration of digital tools into surface integrity inspection processes has revolutionized how inspections are conducted. These tools not only enhance the capabilities of traditional methods but also offer new ways to analyze and interpret data.

Digital Radiography: Enhanced Imaging

Digital radiography uses X-ray imaging to inspect internal and surface integrity, similar to traditional radiography but with digital capture techniques that allow for immediate image preview and analysis. This method provides higher resolution images than conventional X-ray film, enabling more precise identification of defects.

Automated Inspection Systems: Consistency and Efficiency

Automated inspection systems combine various techniques, such as ultrasonic testing, laser scanning, and digital imaging, to perform comprehensive inspections with minimal human intervention. These systems are programmed to follow precise protocols and can handle large volumes of inspections with consistent accuracy, significantly reducing the risk of human error.

The Future of Surface Inspection

The field of surface inspection continues to evolve, driven by advancements in technology and a growing need for safety and precision in material applications. Modern inspection techniques not only provide more accurate and detailed data but also offer the efficiency and consistency required in today’s fast-paced industrial environments. As we look to the future, the integration of AI, machine learning, and further automation will likely play a significant role in advancing these techniques, ensuring that surface integrity remains uncompromised in even the most demanding applications. This proactive approach to material quality and safety is crucial for the development of reliable, durable products and for fostering innovation across industries.